1 Lungiselela ngaphambi komhlangano

1.1Qinisekisa ukuthi uxhumano lwe-flange olukhethwe njenge-ISO 6162-2 luhlangabezana nezidingo zohlelo (isb. ingcindezi elinganiselwe, izinga lokushisa njll.).

1.2Qinisekisa ukuthi izingxenye ze-flange (isixhumi se-flange, i-clamp, screw, i-O-ring) nezimbobo zihambisana ne-ISO 6162-2

1.3Qinisekisa ukuthi izikulufu ezifanele, i-metric yohlobo loku-1 kanye neyintshi yohlobo 2.

1.4Qinisekisa ukuthi awuhlanganisi izingxenye nezingxenye ze-ISO 6162-1.Indlela yokubona umehluko ohlukile"Indlela yokuhlonza i-ISO 6162-1 kanye ne-ISO 6162-2 flange uxhumano nezingxenye"isixhumanisi.

1.5Qinisekisa ukuthi konke ukuvala nokuhlangana kwendawo (kufaka phakathi izingxenye zembobo ne-flange) azinawo ama-burrs, ama-nick, ama-scratches nanoma iyiphi into yangaphandle.

2 Indlela yokuhlanganisa ngendlela efanele

2.1Ukusiza ukunciphisa i-O-ring scrub-out, gcoba i-O-ring ngejazi elikhanyayo loketshezi olusebenzisa amanzi asetshenziswa ohlelweni noma uwoyela ohambisanayo, uma kudingeka.Thatha ukunakekelwa okukhethekile, njengoba i-lubricant eyeqile ingakwazi ukuphuma ehlangene futhi iholele ekukhombeni okungamanga kokuvuza.

Qaphela:Osayizi bendandatho ye-O babona ithebula 1 noma ithebula 2, futhi inosayizi ofanayo wesikulufu se-metric noma esiyintshi, ilingana nosayizi we-ISO 6162-1 kanye ne-ISO 6162-2 yokuxhumana kwe-flange, ayikho inkinga exubile.

2.2Misa ikhanda elivulekile kanye nezinsimbi ze-flange.

2.3Beka amawasha aqinile ezikulufini, bese ufaka izikulufo emigodini yezinsimbi.

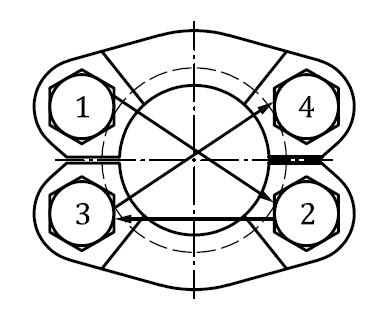

2.4Isandla qinisa izikulufu ngokulandelana okuboniswe kuMfanekiso 1 ukuze uqinisekise ukuthintana okufanayo kuzo zonke izindawo ezine ngezikulufo ukuze uvimbele ukugoba kwe-flange, okungaholela ekuphukeni kwe-flange ngesikhathi sokusetshenziswa kwetorque yokugcina.

Umfanekiso 1 - Ukulandelana kokuqinisa isikulufu

2.5Torque izikulufu ngokulandelana okuboniswe kuMfanekiso 1 ekunyusweni okubili noma ngaphezulu ukuya kuleveli yetorque yesikulufu enconyiwe futhi usebenzise osayizi abafanele be-wrench kuthebula 1 lesikulufu se-metric kanye nethebula 2 lesikulufu esiyiyintshi.

Ithebula 1 - Amasayizi we-torque nama-wrench ane-screw metric yokuhlanganisa ukuxhumana kwe-flange okuhambisana ne-ISO 6162-2

| Ngokuzisholo usayizi | Ubuningi ukusebenza ingcindezi | Uhlobo 1 (metric) | ||||||||

| Isikulufa Uchungechunge | Ubude besikulufa mm | I-torque yesikulufa N.m | Isikrini | O-ring | ||||||

| MPa | bar | okwehexagon isikulufu sekhanda mm | okwesokhethi isikulufu sekhanda mm | Code | Iububanzi obuphakathi mm | Cingxenye - ross mm | ||||

| 13 | 42 | 420 | M8 | 30 | 32 | 13 | 6 | 210 | 18.64 | 3.53 |

| 19 | 42 | 420 | M10 | 35 | 70 | 16 | 8 | 214 | 24.99 | 3.53 |

| 25 | 42 | 420 | M12 | 45 | 130 | 18 | 10 | 219 | 32.92 | 3.53 |

| 32 | 42 | 420 | M12 | 45 | 130 | 18 | 10 | 222 | 37.69 | 3.53 |

| 38 | 42 | 420 | M16 | 55 | 295 | 24 | 14 | 225 | 47.22 | 3.53 |

| 51 | 42 | 420 | M20 | 70 | 550 | 30 | 17 | 228 | 56.74 | 3.53 |

| 64 | 42 | 420 | M24 | 80 | 550 | 36 | 19 | 232 | 69.44 | 3.53 |

| 76 | 42 | 420 | M30 | 90 | 650 | 46 | 22 | 237 | 85.32 | 3.53 |

Ithebula 2 - Amasayizi we-torque kanye nama-wrench ane-inch screw yokuhlanganisa ukuxhumana kwe-flange okuhambisana ne-ISO 6162-2

| Ngokuzisholo usayizi | Ubuningi ukusebenza ingcindezi | Uhlobo 2 (intshi) | ||||||||

| Isikulufa Uchungechunge | Ubude besikulufa mm | I-torque yesikulufa N.m | Isikrini | O-ring | ||||||

| MPa | bar | okwehexagon isikulufu sekhanda in | okwesokhethi isikulufu sekhanda in | Code | Iububanzi obuphakathi mm | Cingxenye - ross mm | ||||

| 13 | 42 | 420 | 5/16-18 | 32 | 32 | 1/2 | 1/4 | 210 | 18.64 | 3.53 |

| 19 | 42 | 420 | 3/8-16 | 38 | 60 | 9/16 | 5/16 | 214 | 24.99 | 3.53 |

| 25 | 42 | 420 | 7/16-14 | 44 | 92 | 5/8 | 3/8 | 219 | 32.92 | 3.53 |

| 32 | 42 | 420 | 1/2-13 | 44 | 150 | 3/4 | 3/8 | 222 | 37.69 | 3.53 |

| 38 | 42 | 420 | 5/8-11 | 57 | 295 | 15/16 | 1/2 | 225 | 47.22 | 3.53 |

| 51 | 42 | 420 | 3/4-10 | 70 | 450 | 1 1/8 | 5/8 | 228 | 56.74 | 3.53 |

| 64 | 42 | 420 | - | - | - | - | - | 232 | 69.44 | 3.53 |

| 76 | 42 | 420 | - | - | - | - | - | 237 | 85.32 | 3.53 |

Isikhathi sokuthumela: Jan-20-2022